No products in the cart.

Manufacturing concrete restoration solution and old concrete floors for use in industrial halls, parking lots, warehouses, etc. by Dasco research team

Manufacturing concrete restoration solution and old concrete floors for use in industrial halls, parking lots, warehouses, etc. by Dasco research team

Today, the need for lightweight, insulating, economical and formable materials in various forms is one of the essential needs of industrialization and accelerating the speed of construction. One of the major problems in the buildings built especially in recent years is the lack of sound and thermal insulation in the common and surrounding panels and walls, which has caused dissatisfaction and discomfort among consumers.

Therefore, the research team of Dasco company, with the efforts of its experts and after 7 years of research work and studies that are presented on all modern and new materials in the construction industry as light and insulated walls around the world and especially in the countries of opinion, the product Register your induction and insulation ultra-light concrete, which was made and produced for the first time in the world, in the Patent and Intellectual Property Organization of Iran.

Participating in the patent competition of the International Federation of Inventors of the World in 2022 in Switzerland and receiving the world silver medal is a confirmation of the unique and exemplary technical characteristics of this innovation and invention.

This product is a kind of porous and hard ultra-light concrete consisting of cement, water and nano-micro silica with a density of 150 to 900 kg/m3, which uses ionic repellency to create porosity and lighten it.

Induction light concrete is a very suitable and hard sound and thermal insulation product that can be produced and pumped up to a distance of 70 meters in an induction mixer. Significant reduction in insulation costs compared to stone wool, polyurethane and…

The increase in the hardness of separating walls and the high speed of implementation are the advantages of ultra-lightweight concrete. This type of light concrete is produced by the induction method, which will make the voids created in light concrete lighter and more stable.

Unlike foam concrete, which has an open cell structure and water easily passes through it, light induction concrete consists of a closed cell bubble structure, which prevents the transfer of water and moisture through its thickness.

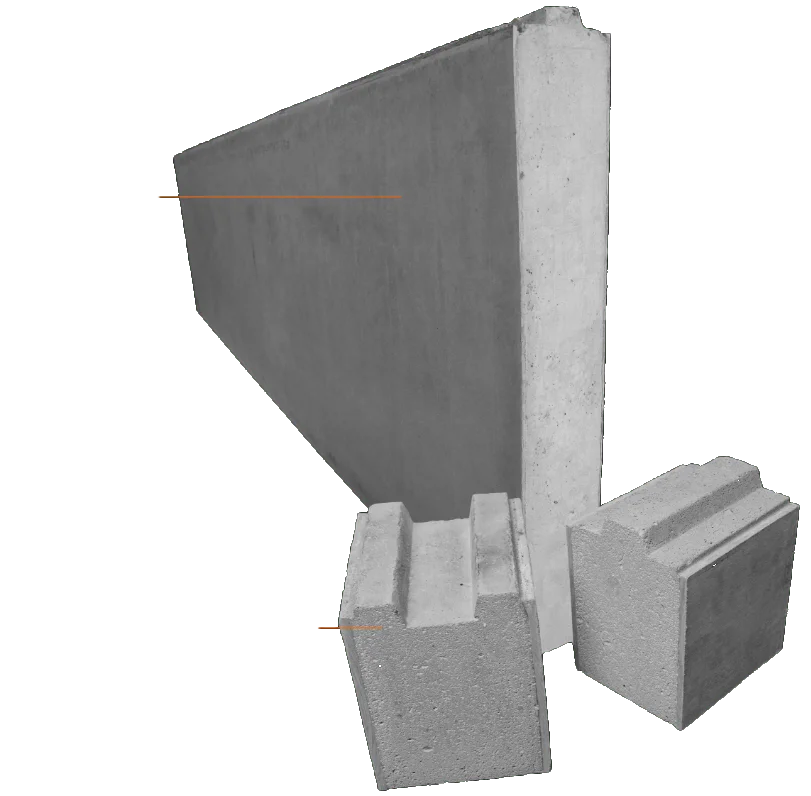

The production and construction of puzzle blocks without the need to use mortar or glue during installation, panels with a height of one floor for the construction and implementation of internal and peripheral walls with the ability to install screws and nails on its surface without restrictions is one of the most popular applications of this technology.

Among the other uses of light-weight concrete, we can mention the insulation of facilities buried in the ground and the stability of structures in fire.

In order to produce insulated lightweight concrete in the workshop, a portable workshop machine can be used for the purpose of making, transferring and injecting insulated lightweight concrete to fill the empty space of prefabricated walls of dry wall systems and light structures such as LSF.

This single-phase device is portable and can fill 30 to 40 holes in the walls of the kenaf every hour.

Construction speed is 3 to 5 times faster than light blocks and traditional methods

Ability to connect nails and screws without restrictions on the entire surface of the wall

Significant reduction of sound waves in the walls and floor and elimination of disturbing sounds

Preventing the transfer of cold and heat from outside to inside and vice versa

Very long resistance against any fire and fire for more than 5 hours

50% lighter than the light walls available in the construction market